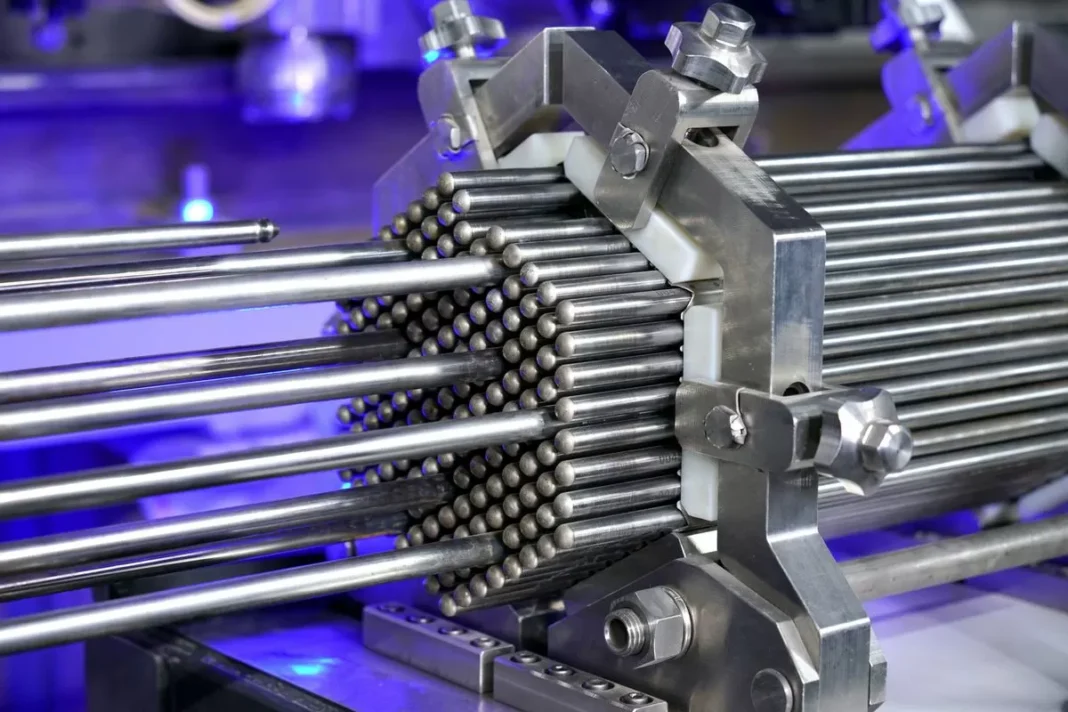

The fuel fabrication/refabrication module is a vital component of the unique 4th generation nuclear energy complex. This revolutionary technology is at the forefront of the future of nuclear energy, providing a safe, efficient, and sustainable source of power for generations to come.

The fuel fabrication/refabrication module is responsible for producing and recycling the nuclear fuel that powers the reactor. It is the first of its kind and represents a significant advancement in the field of nuclear energy. This module is a key element in the overall design of the 4th generation nuclear energy complex, which aims to address the challenges of today’s energy demands while also ensuring a cleaner and more sustainable future.

One of the main advantages of this module is its ability to produce nuclear fuel from a variety of sources. This means that not only can it use traditional uranium fuel, but it can also utilize recycled nuclear waste, reducing the amount of radioactive waste and minimizing the environmental impact. This is a crucial step towards achieving a truly sustainable nuclear energy system.

But what sets the fuel fabrication/refabrication module apart from traditional methods of producing nuclear fuel? The answer lies in its innovative design and advanced technology. This module incorporates cutting-edge techniques such as laser isotope separation and electrochemical processing, making it a highly efficient and cost-effective way of producing nuclear fuel. It also boasts a high degree of automation, reducing the risk of human error and increasing safety.

Another significant advantage of this module is its flexibility. It can easily adapt to changes in the demand for nuclear fuel, making it a highly versatile and reliable source of energy. This flexibility is essential in today’s ever-changing energy landscape, where we need to be able to adjust our energy sources quickly and efficiently.

Moreover, this module is designed to operate in a closed-loop system, meaning that the nuclear fuel it produces can be recycled and reused multiple times. This not only reduces the amount of nuclear waste but also ensures a more sustainable use of resources. It is also worth noting that the fuel fabrication/refabrication module is designed with safety in mind. It incorporates multiple safety features, including fail-safe mechanisms, to ensure the highest level of protection for both workers and the environment.

The fuel fabrication/refabrication module is an essential component of the 4th generation nuclear energy complex, but it is just one piece of the puzzle. The complex as a whole is designed to be a fully integrated and self-sustaining system, with each component working together seamlessly to produce clean and reliable energy. This innovative approach to nuclear energy sets it apart from previous generations and makes it a game-changer in the world of energy production.

Furthermore, the fuel fabrication/refabrication module is a testament to the continuous progress and advancement in the field of nuclear energy. It is a result of years of research, development, and collaboration between scientists, engineers, and industry experts. This module represents a significant step towards achieving a more sustainable and efficient energy future.

In conclusion, the fuel fabrication/refabrication module is a groundbreaking technology that is set to revolutionize the world of nuclear energy. With its innovative design, advanced technology, and commitment to safety and sustainability, it is a vital component of the 4th generation nuclear energy complex. It is a shining example of the progress and potential of nuclear energy and serves as a reminder that we are constantly moving towards a cleaner and more sustainable energy future.